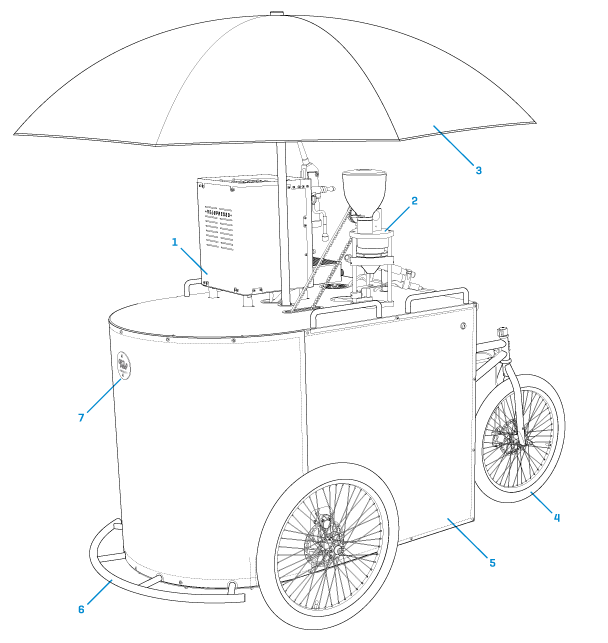

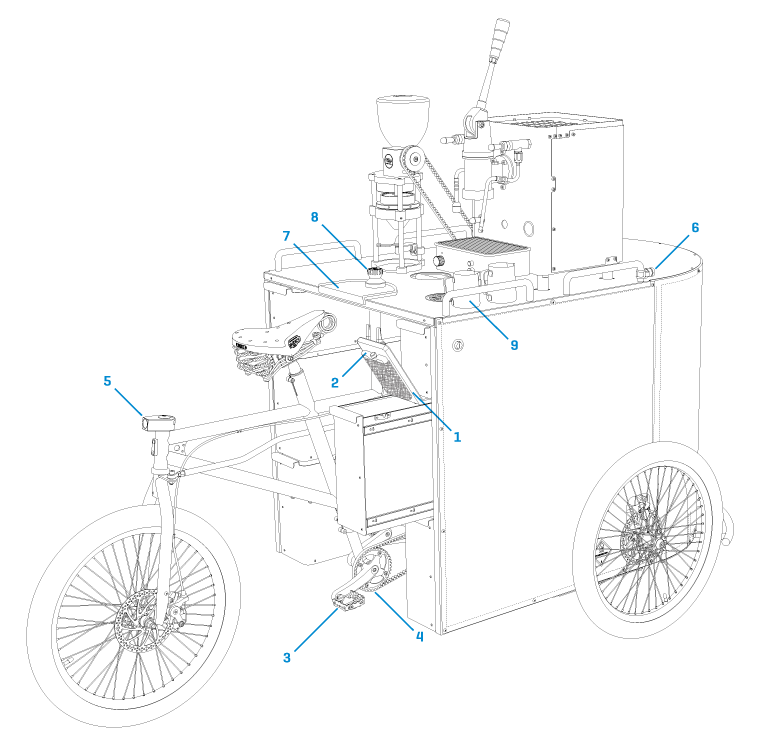

The Velopresso is a unique and highly innovative coffee trike – a complete mobile café – that combines great mobility and excellent espresso machinery with an ultra low carbon footprint and pedal-powered operation that requires no electricity. The machine is designed to perform beautifully, with minimal maintenance, and built to last. All our unique componentry – from the grinder, to the transmission, to the frame parts and accessories – are precision engineered here in Britain. Every Velopresso is built by hand in our east London factory, from the TIG-welding of the steel trike frame-sets to the final assembly and testing, and proudly bears the Made in Britain marque etched on it’s data plate.

- Espresso machine: FCL1-Velo, gas-fired*, commercial spring-lever machine

*dual fuel (gas/electric) option available in UK, EU, AUS, NZ and additional countries world-wide, please enquire for further details - Grinder: GR1-Velo, pedal-grinder, with conical Ø71mm burrs, no electricity required

- Umbrella*: 2.4m canopy, fibreglass frame, aluminium pole *recommended accessory

- Wheels: strong and light Halo SAS DH pro alloy wheels, custom built for Velopresso, 24” rims, 48 spoke, 20mm through axles

- Branding panels: 3 square metres for your branding / artwork, digitally printed, full-colour, weatherproof, fire retardant PVC* fabric panels, bolt-on

*EU Reach approved, recyclable - Bumper: stainless steel (304) bumper, bolt-on

- Marque: stainless steel Velopresso marque, bolt-on, secures front panel

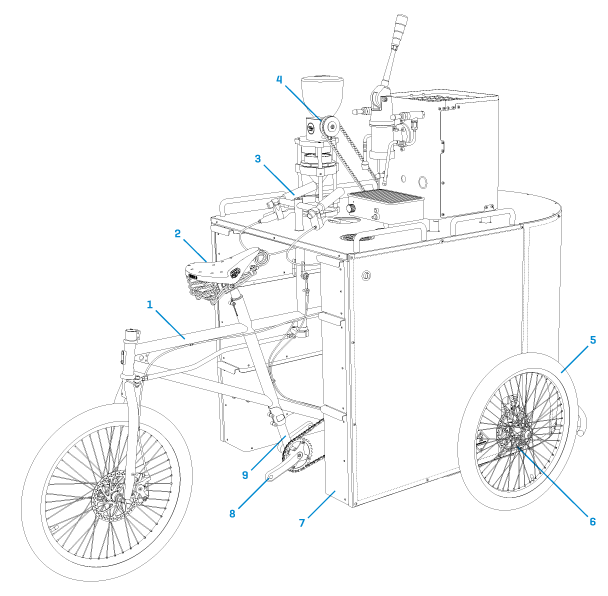

The Velopresso tricycle is designed to meet the structural, spatial and ergonomic requirements necessary to locate and transport the combined weight of the cyclist, machine and supplies, and allow from-the-saddle operation of the coffee machinery. Rear-wheel steering allows the trike to turn on the spot. The handlebars are removable to give a clear work area when in coffee-mode. Two levers operate the 3-speed hub gear and clutch – which switches the transmission from ride-mode to coffee-mode where pedalling directly drives the grinder and water pump. Six key-lockable aluminium drawers provide the main storage. The Gates Carbon Drive™ system is used at the grinder for clean and maintenance-free operation, while chain is used at the cranks (pedals) for quick rider height adjustment. Hydraulic twin disc-brakes provide efficient stopping power.

* Gates Carbon Drive™ system available at the cranks also, but as a custom option, and is suitable for single-user trikes only

- Frame: Reynolds 631 plain gauge steel alloy tubing and mild steel, powder-coated black* (RAL 9005)

*colours available – see custom options - Saddle: Brooks B33 sprung leather delivery saddle – for optimal all day comfort

- Steering: stainless steel (304) handlebar unit and steerer-rod, aluminium tiller / steerer clamp

- Grinder belt: Gates Carbon-Drive™ drive belt is used at the grinder

- Tyres: Schwalbe ‘Crazy Bob’ super-strong reinforced cruiser tyres give cushioned ride

- Disc brakes: Magura ‘Big Twin’ hydraulic (front), mechanical (rear), parking brake lever

- Drawers: aluminium, key-lockable, 2 × small, 4 × large (receive insulated coolbox inserts* for milk storage up to 24 litres / 48 pints) *accessory

- Cranks: short 150mm cranks, with a low gear (32T) chainring and chain is the new standard

- Boom bottom bracket: stainless steel telescopic boom for rider height adjustment

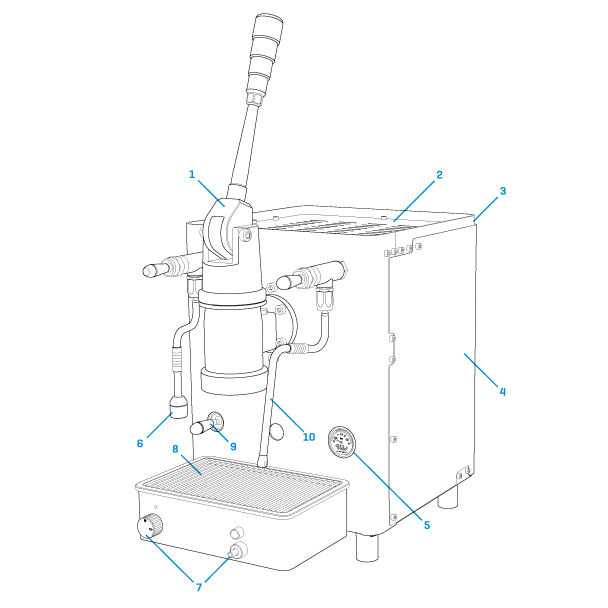

FCL1-Velo espresso machine

The FCL1-Velo is a gas-fired* commercial spring lever espresso machine designed for the Velopresso in collaboration with its award-winning UK manufacturers Fracino. Commercial lever machines are simple to operate, very forgiving, and widely regarded as delivering exceptional espresso with rich crema, high solids, and a fine buttery mouthfeel. The lever group used is the best available, while the 7-litre copper boiler is heated by a powerful but silent burner running on LPG. A pedal-driven rotary pump synced to the grinder refills the boiler with water as it is used. A powerful steam tube for steaming milk, a stainless steel hot water outlet and unique rattle-free silicon drip tray with stainless steel grille complete the machine. With its’ superb build quality, the FCL1-Velo is one of the most robust and reliable mobile espresso machines.

*dual fuel (gas/electric) option available in EU and additional countries world-wide, see Custom Options in Specification for more details

- Commercial (58mm) spring-lever group: forged brass group, polished chrome

- Boiler: 7L copper boiler with powerful 1.8kW rated LPG gas burner*

- Chassis: steel chassis, powder-coated black* (RAL 9005) *colours available – see custom options

- Stainless steel cover: vented with laser-cut ‘Velopresso’ type logo on rear

- Boiler pressure gauge: with Velopresso logo

- Hot water valve: stainless steel tube, anti-splash nozzle, push-to-lock-on / flick operation

- Gas controls: on/off setting, pilot and piezo-ignition controls

- Drip tray: stainless wire grille in silicon ‘rattle-free’ tray, plumbed-in waste connection

- Water inlet valve: lock-in-position lever valve

- Steam tube: stainless steel, 4 hole steam nozzle, push-to-lock-on / ‘flick’ operation lever

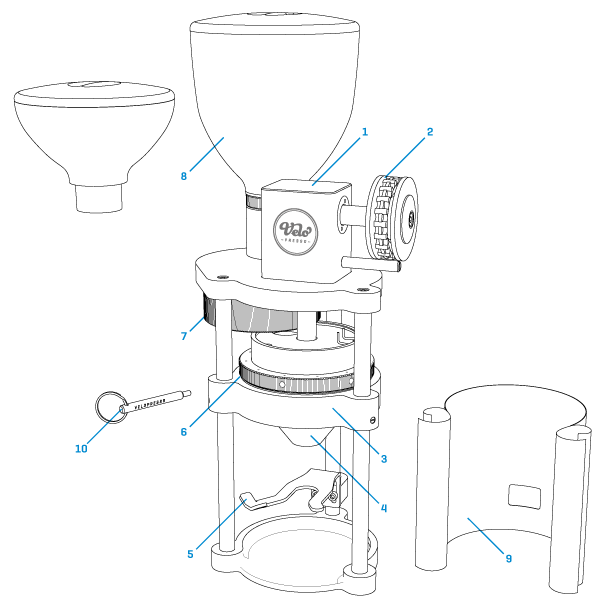

GR1-Velo grinder

The GR1-Velo is the first pedal-driven commercial coffee grinder in the world. Precision engineered to last a lifetime* in stainless steel, hard-anodised aluminium, and polycarbonate, the grinder uses large 71mm conical burrs, has stepless grind adjustment, volumetric pre-dosing of beans and very low grind retention. The grinder is directly pedal-driven, so there is no electricity required and therefore no motor noise or possibility of electrical failure. Easy pedalling at 90 – 100rpm gives 300 – 400rpm at the burrs, grinding a double shot in 5 – 10 seconds with no overheating of the beans. The magnetic grind funnel and bolted assembly allows for easy dismantling for cleaning and burr changes. A removable wind screen (9) and grind adjustment tool (10) is supplied. GR1-Velo: rapid, fresh, cool and efficient on-demand grinding by pedal-power!

*burrs need replacing periodically according to use

- Gearbox: stainless steel shafts, hardened gears, silent, sealed unit with foodsafe grease

- Drive sprocket: Gates Carbon-Drive™ CenterTrack™, 22T sprocket, 9-spline mount

- Burrs: conical Ø71mm steel burrs – ‘Mazzer Robur’ type, typical rpm range 300 – 400

- Grind funnel: magnetic stainless steel for easy access to clean the burrs, guides coffee grinds direct from burrs to portafilter

- Portafilter support fork: height adjustable with handle rest, stainless steel, electropolished

- Grind adjustment collar: stainless steel, precision stepless grind adjustment

- Doser: volumetric rotary bean doser, can be set to nominal 9g or 8 or 7g single doses with reducer sleeves, rotate twice for double shot

- Hopper: the hopper mount is compatible with all Compak K-series hoppers, a 0.8kg* extra-strong Makrolon® hopper is supplied

*the smaller 0.3kg hopper (also illustrated above) is available as an accessory

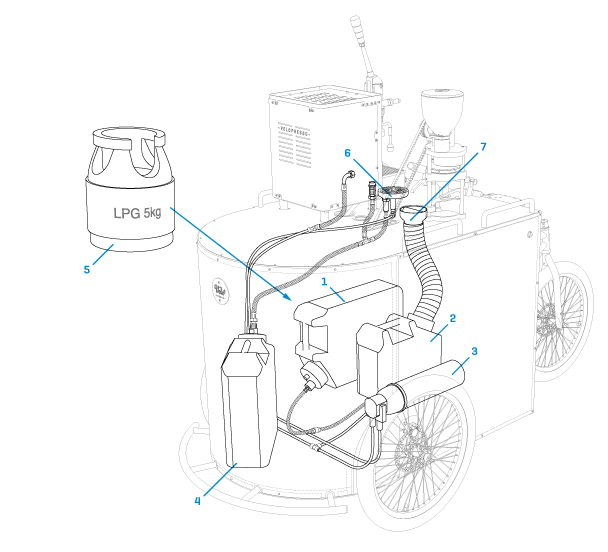

Utilities

Velopresso is all about efficiency and all the utilities are secured with webbing straps fitted with strong snap buckles or Velcro for quick set-up and removal. The blue 20L* Scepter MWC fresh water tank has a quick-release coupling (QRC) with stop valve that connects it to the rotary pump (pedal-driven), which pushes the water either direct to the on-board pitcher rinser sink or with the switch of a lever to the espresso machine via the water filter. The fresh-water hose connections, tanks and pump are all designed for potable water use. Liquid waste is collected in the black 20L MWC waste tank fitted with a QRC. Waste coffee pucks are collected in a black 10L MWC via the knock bar, stainless steel funnel and smooth-bore ducting. A bolt-on aluminium shelf with rubber pad supports a gas cylinder (not supplied) of 1.8kg to 5kg, providing up to 10 days use (average consumption is 0.5kg per day).

- Fresh water tank: blue 20L* Scepter MWC, hoses and QRC suitable for potable water use

*a 10L fresh-water tank can be supplied as an alternative or accessory - Knock box tank: black 10L Scepter MWC

- Filter: Brita Purity Quell ST C300 cartridge, Brita Purity C 30% head

- Waste liquid tank: black 20L Scepter MWC, hoses and QRC

- Gas cylinder*: LPG gas, propane or butane

*the gas cylinder, regulator and gas hose are not supplied as must be sourced, fitted and certified locally - Pitcher rinser sink: pedal-driven cold water pressure rinser for milk jugs, stainless steel sink, Celli rinser mechanism, plumbed in

- Knock bar and funnel: bolt-on black plastic knock bar, spun stainless steel funnel, smooth bore ducting

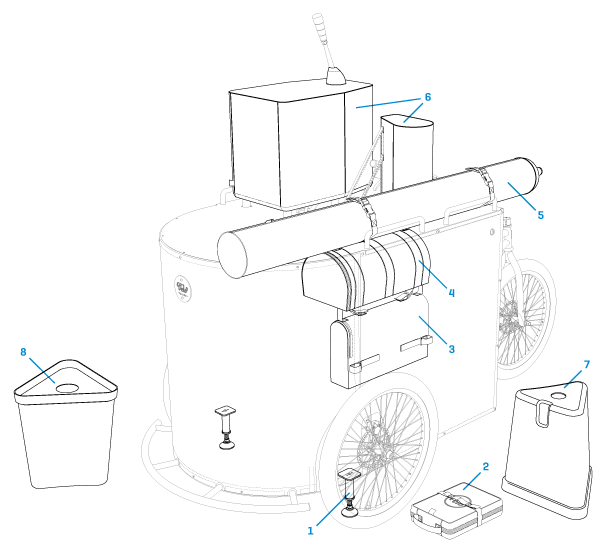

Accessories

The key accessories listed on these pages are all designed specifically for the Velopresso: the umbrella (plus umbrella transit bag), protective machine covers, jack stands, coolbox inserts, ice packs and storage bags are all regarded as essential items. The umbrella is strong and lightweight and completes the look and function of the Velopresso; the multifunctional jack stands are quick to bolt in place and both level and steady the trike in coffee-mode and support the trike in the rare event of a puncture. The VP toolkit provides nearly all the tools you will ever need in normal use, (plus space for the jacks and a pump) in a smart bespoke bag that straps inside the trike. The tough waterproof storage bags provide space for supplies, machine covers and hopper when not in use. Up to 4 Roto Stacka stools and a waste bin can stack inside the Velopresso, providing onboard customer seating and a waste bin to complete the mobile cafe.

- Jack stands: multifunctional support legs, welded stainless steel, bolt into place

- Velopresso toolkit: 21 piece toolkit including specially designed toolbag, and transit strap

- Storage bag (small): weather resistant nylon (orange) bag for up to 300 paper cups

- Storage bag (large): weather resistant nylon (orange) bag for hopper, beans, etc.

- Umbrella & umbrella bag: 2.4m (8’) diameter, UV and water proof, certified fire-retardant; aluminium pole, fibreglass frame and fittings. Weather resistant nylon (black) bag to match protective covers, supplied with shoulder and transit straps

- Protective covers (espresso machine & grinder): weather resistant nylon (black) covers with reflective piping

- Rotostacka stool: tough stackable customer seating in various colours

- Rotostacka waste bin: based on the stool with stainless steel lid and sealed base

Accessories continued

The coolbox inserts are highly insulated liners that fit precisely into the 4 large aluminium drawers. Used with our ice packs they provide excellent cold storage for up to 3 x 2 litre (4 pint) containers of milk in each drawer (24 litres / 48 pints total). Best pedal-grinding technique requires click-in (e.g. SPD) pedals and cycling shoes. A heavy-duty tamping mat provides the perfect work area and also covers the handle-bar mount. Our low and heavy VP Tamper has been developed with the specific from-the-saddle ergonomics in mind. The rear clamp light is our elegant 2-in-1 solution that replaces the standard twin-clamp, while also neatly housing a Lezyne Femto LED rear light. Matching Femto front lights fit on the hand rails. With cold-water pressure rinsing, non-stick milk pitchers are ideal. Trikes with a single dedicated barista can be fitted with the low maintenance and grease-free Gates Carbon-Drive™ CenterTrack™ system at the cranks as a custom option.

- Coolbox insert: insulated flat-pack drawer liners used with 5 or more freezer blocks provide exceptional cold storage for milk

- Ice packs: Kampa ice packs (200ml x 5) fit precisely into the coolbox inserts

- Pedals: click-in (e.g. SPD) pedals and cycling shoes are recommended – see page 10 for further information

- Gates Carbon-Drive™ CenterTrack™ belt system (see Custom Options)

- Rear Light: CNC-machined aluminium clamp light, hard anodised black (or silver), matching top cap, and Leyzne Femto rear light fitted

- Front lights: Lezyne Femto, silver, LED

- Tamping mat (‘Lippy’): heavy duty, long lasting tough rubber tamping mat with the perfect lip

- VP Tamper: CNC-machined stainless steel base, aluminium handle, colour and laser engraving options, 510g, 58.5, fits VST and VP

- Milk pitchers (12 and 20oz): black, non-stick

Click to download full Specification (PDF 1.9MB)

Velopresso Ltd reserve the right to change the above specification without notice

© Velopresso Ltd, 2022